Features

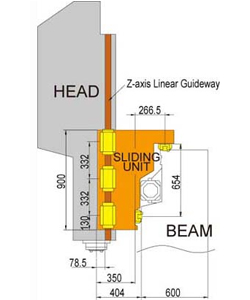

ROLLER TYPE LINEAR WAYS ON THREE AXES

- All major structural parts are manufactured from high quality cast iron with tempering tread to relieve stress, ensuring maximum material stability without deformation.

- Box type structural parts are rib reinforced to increase structural strength and rigidity.

- Extra heavy base complete support of table and resists heavy load without deformation.

- X, Y, Z axis are mounted with roller type linear ways combined with extra wide between ways for added stability.

32 TOOLS CHAIN TYPE MAGAZINE (STANDARD)

- The magazine is driven by a precision cam, featuring fast and accurate tool positioning.

- Tool selection is bi-directional and random for fast tool change.

- The magazine accepts ISO 50 tool shank.

- The magazine is separately mounted from the cutting area combined with a protection door to prevent tools contamination from chips or coolant.